The Problem:

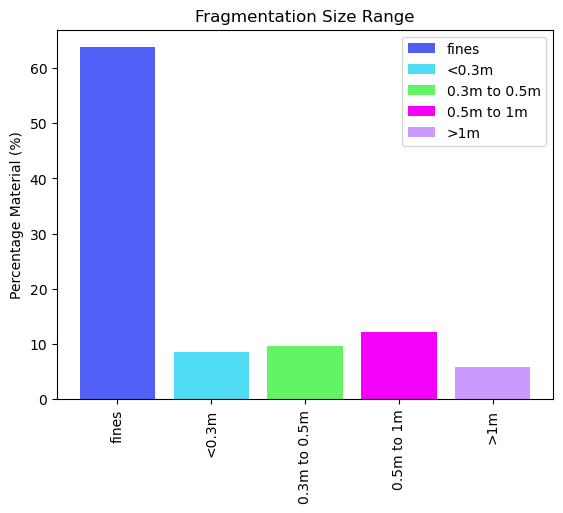

An open cut iron ore mine in North America required a fast, reliable way to quantify fine material in blasts. Excessive fines created challenges with shovel loading efficiency. Crusher performance was also impacted when excessive fines cause blockages or reduced throughput. The problem was indicative of the need for improvements in blast design to achieve consistent size distribution and reduce explosives and consumables use.

The mine needed a fast, reliable way to quantify fines material as a proportion of the total blasted pile to guide refinements in blast design so that production rates met the mine plan and crusher delays were minimised.

The Solution:

PETRA was able to provide the FRAGx solution enabling the characterisation of fragmentation quickly, accurately and without any investment in new sensors or training. The mine already used a number of terrestrial laser scanners for survey tasks around the mine.

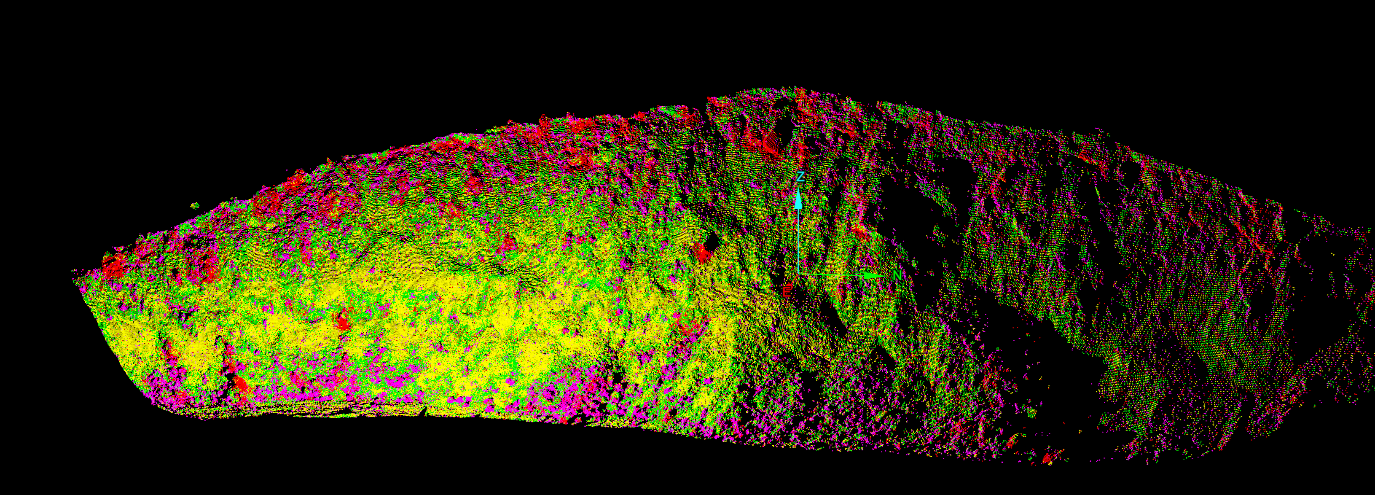

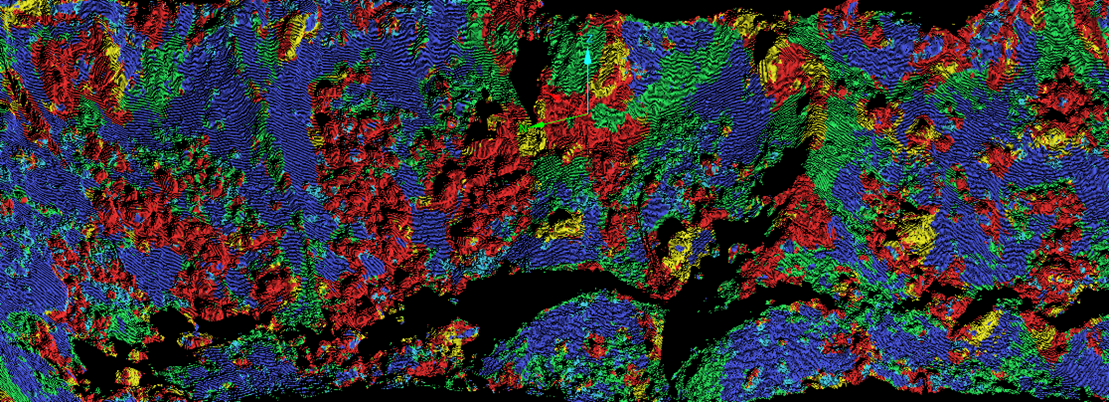

These scanners able to capture data at a suitable resolution and precision to allow the FRAGx software to analyse fragmentation performance directly from the scan data. FRAGx uses machine learning models working directly on 3D point clouds to determine the range and distribution of particle sizes visible in a scene and reports to the user within minutes of the data being available. FRAGx is available as a plug-in for Maptek’s PointStudio software, meaning that this task could be quickly conducted by surveyors as part of their regular workflows and without the need for any training.

As well as quantifying fines material, the FRAGx solution was trained to identify oversize rocks in a blast also. This solution was preferred as it used the existing measurement capability at the mine, did not interrupt the existing survey workflows and was fast and easy to implement and get results.

The Implementation:

Implementation of the solution began with PETRA technical specialists reviewing the available measurement data and the customer requirements to ensure the data being collected would be suitable.

The parameters of many laser scanners can be adjusted by the user and PETRA will advise on the ideal data density and range to achieve the required results, but in this case the standard survey pickups were suitable without change.

PETRA worked directly with the blast engineers and surveyors to train and configure the FRAGx solution, and once requirements are agreed PETRA works to train machine learning models specifically for the customers data and reporting objectives. This configuration and training took about a week, following which a trained set of models were tested extensively on additional test data supplied by the customer and then delivered to the customer to use with FRAGx.

FRAGx is very simple to use, requiring no training. Within the PointStudio graphics environment, users only need to select the region of interest to analyse and hit the FRAGx icon and the rest is automatic – a report is available within a minute or two. FRAGx can be applied to any data you may have available enabling consistent, regular metrics on fragmentation performance to be established.

The Results

The regular reporting of fines % and identification of oversize has allowed the mine to identify blast designs improvement opportunities, as well as avoid production delays due to excessive fines or oversize in the crusher. This helps with adherence to production schedules, as more consistent blast fragmentation means load and haul rates are more reliably aligned to schedule assumptions. Avoiding crusher delays or blockages means less downtime, with each crusher downtime event costing a minimum of $20,000 lost production.

The FRAGx solution described here was implemented and delivered for less than $50,000 and will easily create both a productivity improvement and reduce costs through improved blast product and consumables use, better shovel efficiency and avoiding crusher downtime. The mine now has improved benchmarks for blast design and a consistent historical measure of performance to help guide further improvements to blast design in the future.