The Problem:

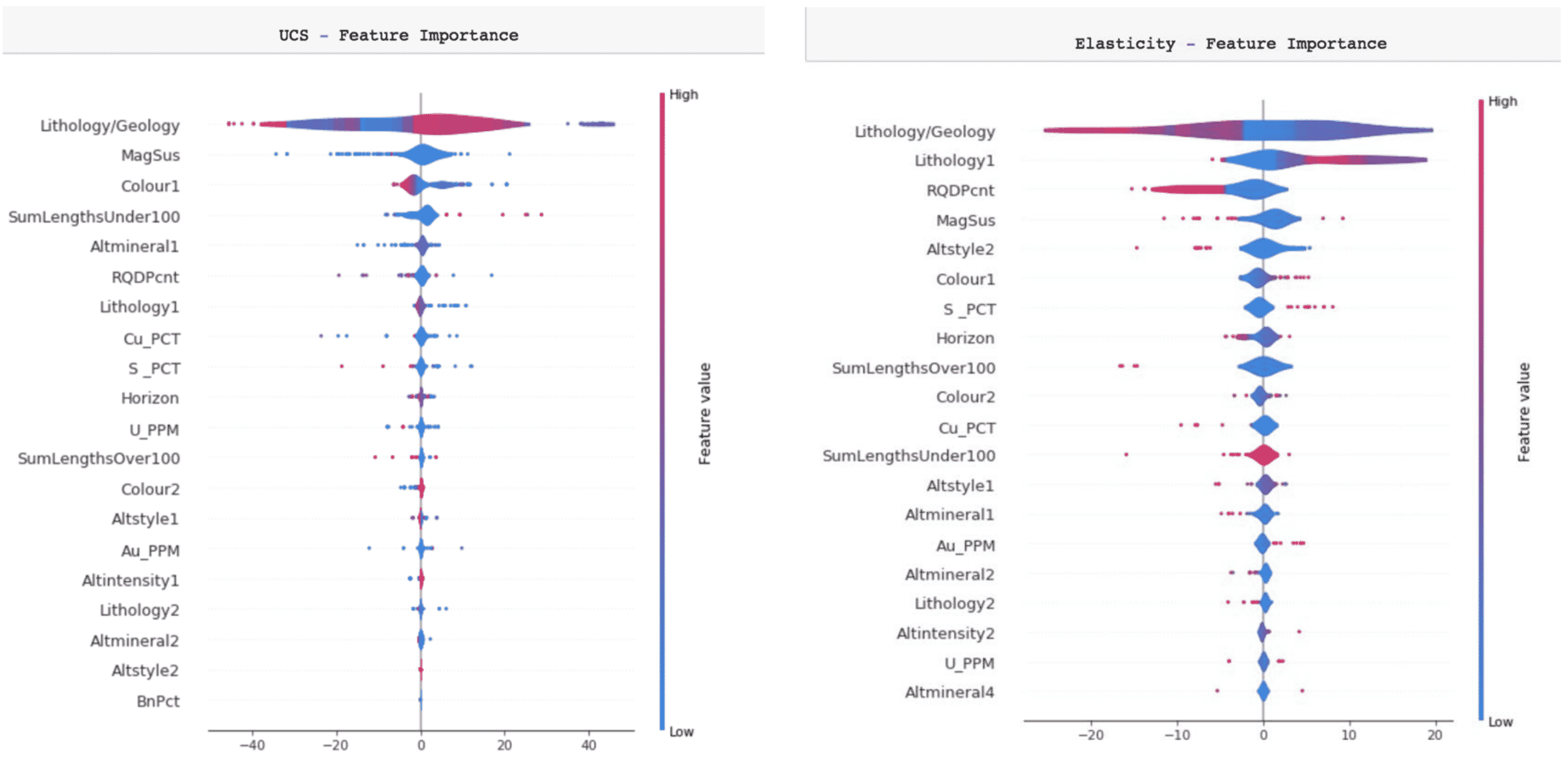

In 2019, an underground project study team in South Australia was looking for new ways to improve rock strength estimates because standard lithological domaining techniques produced typically high standard deviations of 20-50%. As per standard industry practice, rock testing costs limited the granularity and variability captured in the block model to the scale of 16 lithological domains.

Mining and geotechnical engineers involved in the study required reliable estimates of rock properties for; mine design, ground support design, numerical modelling and fragmentation modelling.

Each of these studies required reliable estimates of the mechanical rock properties including:

- Rock strength e.g. Uniaxial compressive strength (UCS)

- Modulus of elasticity e.g. Young’s modulus (E)

- Density

The Solution:

ROCKRay by PETRA Data Science was the chosen solution as it was capable of filling in laboratory rock testing results along untested lengths of core and enabled the team to estimate rock testing results at the block model scale. Using optimised data fusion and machine learning it promised to:

- reduce the need for extensive drill core sampling and time consuming laboratory tests,

- turn hundreds of drill core test results to thousands of predictions along uncharacterised lengths of drill core

- allow engineers to simply upload drill core data and receive packaged predictions in less than 8 hours

The Results:

The ROCKRay implementation project was complete within six weeks and enabled the project study team to build high granularity 3D block models by providing team with 190 fold increase in the amount of core length with rock strength estimates available for engineering design and 3D ore body modelling.

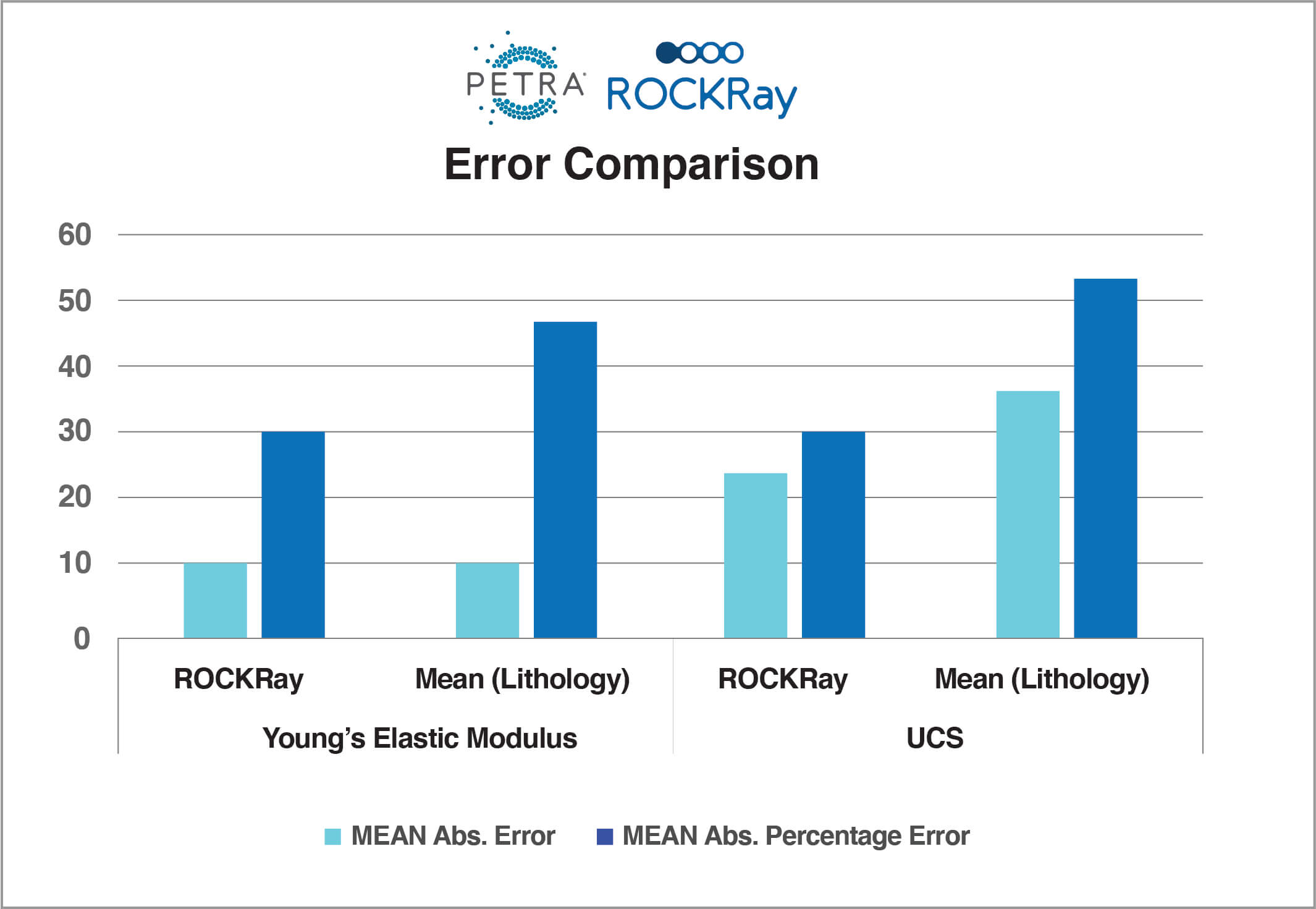

Before implementing the machine learning software, the site had approximately 30 metres of rock sample laboratory test results for 16 lithological domains from 28 holes. After using ROCKRay the team had access to 5690 metres available for 3D block modelling. This meant the study team had block model scale estimates of rock strength that were significantly more accurate that the lithological mean – see error comparison chart.

“This is an exciting step forward for UCS modelling!

With any measurement that is poorly represented in a dataset, we typically can only apply an average value to the entire domain and have to accept the high level of uncertainty a single average gives us. Using machine learning to find how UCS correlates with geological, geotechnical and analytical measurements and then predicting UCS for the entire length of a drillhole moves us towards utilising our data fully and understanding our deposit in a lot more detail.”

Richard Jackson, – Technical Lead, Geology at Maptek

ROCKRay is available now for demonstration, please contact us to arrange a walk through.