Enterprise-grade orebody learning software for value chain optimisation

Why MAXTA?

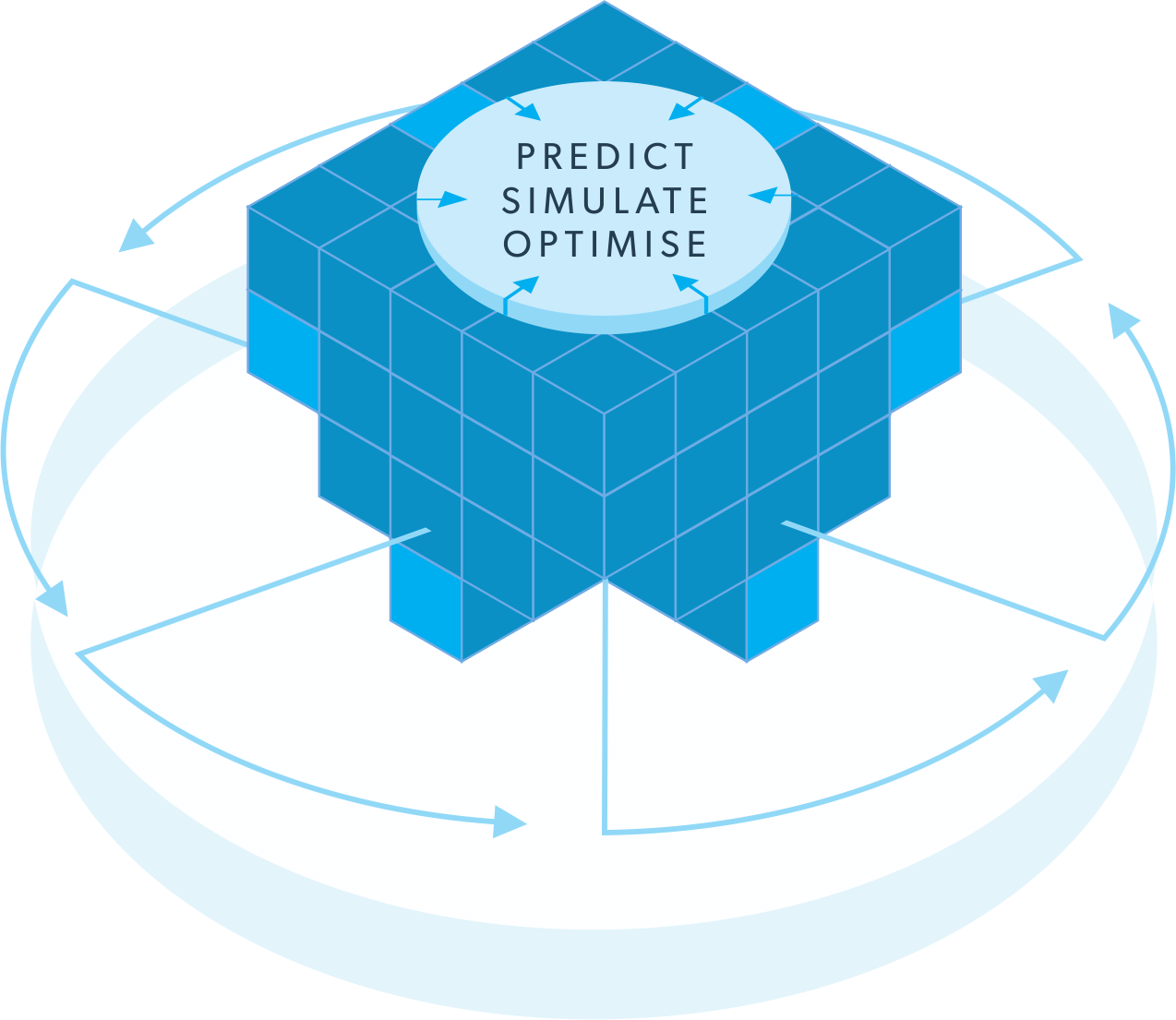

Obtain fast and actionable results from decision support applications

Drive business improvement day-in day-out through the cumulative impact of engineering decisions from planning through to product recovery.

See geological variability as an opportunity for optimisation

Link downstream productivity, efficiency and yield to your geological block model using the world’s first data fusion ore tracking technology.

Achieve your best day everyday

Optimal operating decisions are learned by the software and show engineers how to achieve their best day every day.

Software purpose-built to tackle poor quality mining data

Add new high accuracy orebody learning variables to the block model using data fusion ore tracking and machine learning.

Presenting MAXTA Suite

Add-Ons

Combine with MAXTA to add insights, automation and optimisation to each digital twin application

Want to extract value from your mining data?

Get in touch with the PETRA team to discuss what would be a good fit, relevant to your mine.

Request a DemoOur solutions are trusted by the global mining industry