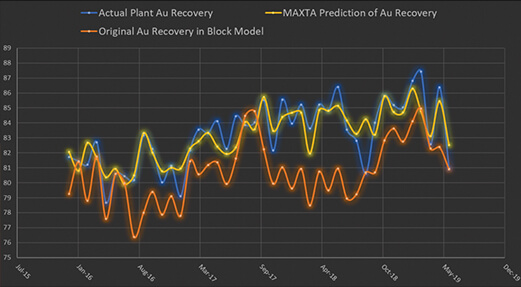

MAXTA predicts gold recovery at Ban Houayxai

The Problem: In 2018, PanAust’s Ban Houayxai gold-silver operation in northern Laos faced a challenging issue: infrequent episodes of […]

Read More… from MAXTA predicts gold recovery at Ban Houayxai

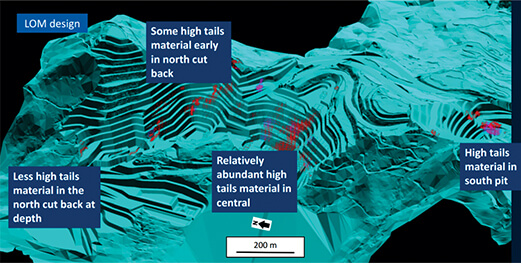

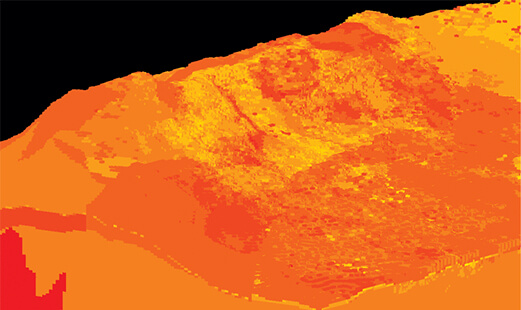

Specific energy contained within the geological block model for improved financial mine optimisation

The Problem: A very large iron ore operation in Australia with multiple AG mill grinding and processing trains required […]

Add-Ons

Combine with MAXTA to add insights, automation and optimisation to each digital twin application

Discover the value of MAXTAGeomet®

Increase productivity, recovery and energy efficiency by showing engineers and supervisors how they achieve their ‘best performance’ through better informed mine scheduling and planning.

Request a demoExplore the full MAXTA Suite

Our solutions are trusted by the global mining industry